What is an Industrial Vacuum System?

An industrial vacuum system is one that is used to take in all solid and liquid materials. This system is not like the vacuum cleaning systems that we might be used to. They are used for transferring materials from one point to the other in industries. Whatever is referred to as a vacuum system in an industry could be a pump system.

An industrial vacuum system is one that is used to take in all solid and liquid materials. This system is not like the vacuum cleaning systems that we might be used to. They are used for transferring materials from one point to the other in industries. Whatever is referred to as a vacuum system in an industry could be a pump system.

This system is more of a pneumatic conveyor than an industrial vacuum. Due to the different needs of industries and the various vacuum models, choosing the most appropriate and effective system can prove challenging.

Pneumatic Conveyor System

This system is operated by pressurized gas or air, thus the name. Materials pass through vertical or horizontal pipes from one place to the other in bulk. The pneumatic conveyor system transfers material through a vacuum or pressure system. A vacuum system is a “negative condition,” while a pressure system is known as a “positive condition.”

The materials get into an input device then pass through a conveying line and out through a discharge device. The materials are transported through the conveyor by a dense phase or dilute phase technology.

In dilute phase technology, the material in transit moves at a high-velocity. The material remains continuously air-borne while being vacuumed or pressured through a pipeline. Dense phase technology transits materials at a lower velocity, and the material is not suspended in the air. The staggering amounts of speed are called slugs.

Benefits of a pneumatic conveyor system

A pneumatic conveyor is flexible. Its versatility allows it to work with any equipment. The pneumatic system does not take much space and is more flexible than other mechanical conveyors. Long conveying distances are no problem for the pneumatic conveyance system to cover. Maintenance costs are lower because the pneumatic system has a few moving parts.

A pneumatic conveyor is flexible. Its versatility allows it to work with any equipment. The pneumatic system does not take much space and is more flexible than other mechanical conveyors. Long conveying distances are no problem for the pneumatic conveyance system to cover. Maintenance costs are lower because the pneumatic system has a few moving parts.

The pneumatic conveyor system features fewer moving parts that allow better sanitation, less spillage, and low noise. The operators will not be exposed to much danger, which means that employees will have safer working conditions. The enclosed pipeline also restricts the amount of dust that gets inside. Less dust means low chances of contamination, thus promoting hygiene standards.

Industrial Pump

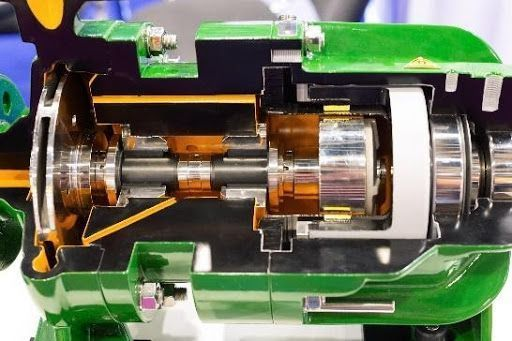

An industrial pump is a piece of robust transportation equipment used to move various materials in industries. The mechanism by which these objects are moved is similar to rotary or reciprocating impellers. The materials being transmitted through this equipment can be in solid or liquid form. These materials can be chemicals, food, oil, gravel, sludge, slurry, etc. The industrial pump has many applications.

Pump Classifications

Industrial pumps are classified into two main groups: centrifugal and positive displacement. They are categorized according to the displacement methods they use to transport items.

-

Positive Displacement Pump

Positive displacement pumps move materials by closing in some amount and forcibly ejecting them through a discharge system. Some of these pumps expand on the suction side and decrease on the discharge side. No matter how much pressure there is on the inlet or discharge end, the flow speed does not change.

-

Centrifugal Pump

This pump uses an impeller to move materials through a chamber. The impeller reduces the pressure at the inlet valve as it rotates inside the housing. The impeller generates mechanical energy that transfers the material to the discharge end. The way the centrifugal pump functions is what makes it known as a negative displacement pump.

Basic Pump Types

Jet Pump Venturi System

Jet pumps force a jet of fluids such as water, air, or steam into a narrowed passage, resulting in differential pressure. The pipe through which the fluid passes is hourglass-shaped. The constricted section’s pressure drops as the fluid flows, and the velocity of the fluid where the pipe becomes larger. The hourglass-shaped pipe is known as the venturi pipe. The jet pump is commonly used to pump well water.

Jet pumps force a jet of fluids such as water, air, or steam into a narrowed passage, resulting in differential pressure. The pipe through which the fluid passes is hourglass-shaped. The constricted section’s pressure drops as the fluid flows, and the velocity of the fluid where the pipe becomes larger. The hourglass-shaped pipe is known as the venturi pipe. The jet pump is commonly used to pump well water.

Liquid Ring Pump

A liquid ring pump is a positive displacement pump that rotates. This pump’s impeller has blades that are attached to a central hub within a cylindrical body. The impeller, through centrifugal force, pushes the fluid to the outer walls of the cylinder. The rotor (impeller) is the only moving part of this pump; therefore, the friction is low. These pumps are common in the oil and gas industry.

Other types of pumps are Rotary Vane Pump, Rotary Screw Pump, and Vacuum Pump.

Where Can I Purchase an Industrial Vacuum System?

You can choose the right vacuum system for your needs at the Think Vacuums store. We have been in the vacuum business for many decades, gaining a lot of experience over the years. Call us today.

References and Resources

Pneumatic vs. aero mechanical conveyors

Log In

Create New Account