A Detailed Guide to Industrial Vacuum Systems.

Definition of Industrial Vacuum System

Industrial Vacuum System is used to transport all kinds of materials; solid or liquid. There are several applications where vacuum systems can be used. The term “industrial vacuum” can be misleading, this is because what might be labeled as ‘’vacuum systems’’ can be a pump system or both. Heavy industrial vacuum systems are designed in a way that they can move a variety of materials by using vacuum and pressure. A term that would be more accurate for these types of vacuums would be “pneumatic conveyor system”, rather than “industrial vacuum”. Below we look at different industrial material transfer systems.

Industrial Vacuum System is used to transport all kinds of materials; solid or liquid. There are several applications where vacuum systems can be used. The term “industrial vacuum” can be misleading, this is because what might be labeled as ‘’vacuum systems’’ can be a pump system or both. Heavy industrial vacuum systems are designed in a way that they can move a variety of materials by using vacuum and pressure. A term that would be more accurate for these types of vacuums would be “pneumatic conveyor system”, rather than “industrial vacuum”. Below we look at different industrial material transfer systems.

Pneumatic conveyor system

A pneumatic system is any equipment that operates via pressurized gas or air. In this system, bulk materials are transported through vertical and horizontal pipes from one point to another. Pneumatic conveying refers to the process of moving various materials through pressure or a vacuum system. A vacuum system is also referred to as a “negative condition” while a pressure system is also referred to as a ‘’positive condition’’. Generally, a pneumatic system comprises an input device, a discharge device, and a conveying line.

This system utilizes the dilute phase or dense phase technology to move the substances. Dilute phase technology is a system where the material being moved is constantly suspended in the air since it’s vacuumed via a pipeline. Dense phase technology refers to substances that move at a slow speed and cannot be moved by air, these substances are referred to as slugs.

Benefits of a pneumatic conveyor system

A pneumatic conveyor system is great because of its flexibility. It can easily work with existing equipment. Additionally, this system uses less space making it the best when working in tight spaces. It is also more flexible compared to standard mechanical systems and has a longer conveying distance. Due to few moving parts, this system requires very little maintenance.

The advanced safety features come with better sanitation, less maintenance, less spillage, less moving parts, and less noise. The risk of danger is substantially minimized for the operators. This can help enhance working conditions for employees by a great margin. There is also less dust as the pneumatic conveyor system encompasses an enclosed pipeline that manages dust in a much better way than the mechanical system. In addition, an enclosed pipeline ensures a clean workplace since it minimizes the chances of contamination.

Industrial pump

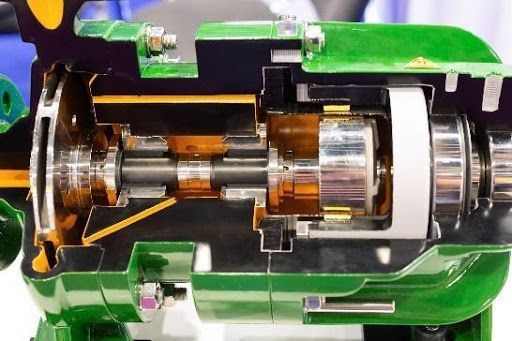

This is a heavy-duty piece of equipment that is solely used to move various types of materials. This is possible as these materials are moved by mechanical action like rotary or reciprocating impellers. Food, water, waste products, sludge, gravel, slurry, oil, and chemicals are some of the materials that are moved via this system. Although, the industrial pump can be used in other ways apart from the one’s mentions.

This is a heavy-duty piece of equipment that is solely used to move various types of materials. This is possible as these materials are moved by mechanical action like rotary or reciprocating impellers. Food, water, waste products, sludge, gravel, slurry, oil, and chemicals are some of the materials that are moved via this system. Although, the industrial pump can be used in other ways apart from the one’s mentions.

Pump classifications

Pumps are categorized based on the method of displacement the pump makes use of to transport material. However, there are various types of pumps; commonly categorized into two key groups, which are: positive displacement and centrifugal.

Positive displacement pump

This pump transports fluids and solids mainly by having a fixed amount of the said material and forcefully making it go through a discharge pipe or system. Some positive displacement pumps come with an expanding cavity on the suction and a contacting cavity on the discharge side. What distinguishes the displacement pump is the fact that it offers the exact same flow at a designated speed regardless of the discharge pressure. The pump will keep up the speed even if the pressure at the inlet is low.

Centrifugal pump

This pump uses an impeller to transport fluid and other substances via a chamber. The impeller rotates thus minimizing the pressure at the inlet valve. This mechanical energy moves fluid and other materials to the discharge side of the impeller. Contrasting to positive displacement pumps, substances being moved will not go at the same speed regardless of the pressure speed at the intake. These pumps are also referred to as negative displacement pumps due to their modes of operation.

This pump uses an impeller to transport fluid and other substances via a chamber. The impeller rotates thus minimizing the pressure at the inlet valve. This mechanical energy moves fluid and other materials to the discharge side of the impeller. Contrasting to positive displacement pumps, substances being moved will not go at the same speed regardless of the pressure speed at the intake. These pumps are also referred to as negative displacement pumps due to their modes of operation.

Industrial vacuums systems make work much easier when dealing with jobs that require intensive transportation of bulky materials like sand and stones. Think Vacuums provides you with all the information you require to know more about these types of systems. Reach out to us and one of our specialists will get back to you with more.

Log In

Create New Account